News

PLASSON Livestock Global Conference 2025

PLASSON Liestock global annual conference

will take place in PQL – PLASSON China, Quigdao, during May 22 – 25, 2025.

Livestock Division Subsidiary Conference

For the first time, the annual conference of the subsidiaries of the Livestock Division took place out of Israel from 4th to 9th December. We chose to hold the conference in Plasson Brazil, where Plasson’s largest subsidiary is located.

The slogan that was chosen to accompany the conference was “Together again”, a slogan that reflected the nature of the meeting after three years of no meetings due to the Corona virus. It was very gratifying and exciting to meet our friends and our partners in daily activities again.

The conference was attended by about 50 people, including the managers of the subsidiaries, marketing and sales managers and technical managers, who came not only from Brazil itself but also from different countries in the world: Israel, South Africa, the USA, Mexico and even a representative from China.

Two and a half days were dedicated to learning and sharing knowledge between the companies, two professional lectures were delivered by external lecturers. In addition an in-depth introduction to Plasson Brazil was held which included a tour of the factory as well as an impressive display of all the equipment produced in their factory, including a new egg sorting machine.

The conference was attended by Plasson’s CEO Gal Wexler, who presented the Plasson vision, as well as Nir Bracha, the new manager of the division, for whom it was an opportunity to get to know all the companies and people.

After the conference we went to Florianópolis, a city on the Atlantic coast for a non-formal activity of deepening the familiarity with a sea atmosphere and Brazilian samba, during a day of boating between the islands.

All the participants of the conference defined the event as extremely successful, educational, consolidating and filling batteries for the continuation of the Division’s activities around the world.

One of the main reasons of the success of the event was the outstanding level of organization and hospitality by the team in Plasson Do Brasil.

Many thanks to all the organizers and to the participants of the conference.

We launched our new Catalog

Our new solutions catalog in progress, enter the catalog to learn more about our systems for Breeders and Broilers.

New Patent by PLASSON

Plasson’s Pressure Reducing Regulators have received a European Patent No. 2,528,430, and a U.S. Patent No. 10,531,645 recognition of the advantages of the reducers.

The reducers are part of Plasson’s unique ‘Water On Demand’ and ‘Water on Demand Pro’ systems that enable to control the pressure in the nipple lines from a central point in each house.

The Reducers are suitable for all poultry farms and can be adapted to all nipple systems.

Tens of thousands of houses already enjoy the advantages of the Plasson, patented, Reducers.

Coupled with Plasson’s newest feature of Wireless Auto-Flushing will greatly improve the productivity in any poultry house.

Water Managment

Would you drink the water you give your birds?

Having clean, safe water is one of the most important factors in the health and performance of your poultry. It also affects egg quality and shell thickness for layers. But the simple fact is that your water supply is vulnerable to minerals, bacteria, algae and more, most of which you may not even be able to see.

The effects of contaminated water

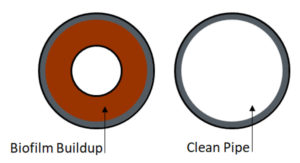

The buildup of the bacteria-friendly ‘biofilm’ that grows inside your watering system causes many issues, including:

- Bio security related concerns of spreading of illness and disease (such as: campylobacter, salmonella, E.- coli, pseudomonas, and staphylococcus )Decreased effectiveness of edications and vaccines dispensed through the water lines

- Decreased bird weight

- Increased feed conversion ratio

- Lack of uniformity in water flow

- Stress on the birds

- Partial blocking of the pipes that can cause malfunction in the regulators or nipples and decrease longevity of the nipples.

In short, contaminated water can increase the vulnerability and mortality of your flock. So, how do you protect against microbial contamination and biofilm buildup? Clearly, it’s not enough to pump in a clean source of water: your pipes need to be cleaned too.

Flushing out your water

One of the simplest ways to do this is to flush the nipple system, thereby washing away the elements that bacteria and other organisms feed off. You are probably doing this already, but are you doing it often enough? It is recommended that you flush your water pipes at least once per day, depending on the climate, house type and bird you are dealing with. We recommend flushing the lines one after the other to ensure that there is enough pressure for the flushing. Flush each line for 10 minutes at least to provide enough time to remove the scale buildup and the bacteria with it.

As well as ensuring the quality of water and the pipe system, flushing helps to maintain an ideal water temperature of around 20˚C (68˚F): chickens don’t like hot water, so if the water gets over 27˚C (81˚F), your flock will drink less, affecting their daily body weight. The heat will also encourage the growth of bacteria within the system, leading to all the problems mentioned above.

Making flushing simple

You may be put off frequent flushing because of the time, cost, water wastage and effort involved – top tier cages in particular can be tricky to reach. Recognizing these challenges, PLASSON with over 50 years of experience has recently completed the innovation development of a new, patent pending, Automatic Wireless Flushing Solution that washes out contaminated water, bringing in a boost of high pressure water that pushes out dirt, bacteria and air pockets, while cooling down the whole watering system.

The new pressure regulators design features an external connecter for improved flow, a choice of three flushing modes: manual, wired or wireless, and three options of sight tube: regular, threaded or detachable. It is easy to maintain, works on 24V and is available as a pressure regulator or pressure reducer.

The innovative wireless option is operated by Bluetooth, named FlushControl, and can be operated from a smart phone with a dedicated app. Each Line head unit can be controlled by a wall base unit with a control radius of up to 30 meters. The wall base unit can be wired to the house control unit. A wall base unit can simultaneously control up to 30 lines.

The Automatic Wireless Flushing Solution is an economical solution that requires no wiring across the house and minimal setup. Simply connect the system to the nipple line that the birds drink from, and use the app on your mobile or tablet to pre-set, change, modify, and switch to manual operation, quickly and easy.

To find out more about PLASSON’s FlushControl Automatic Wireless Flushing Solution, click here>

News

We are pleased to inform you that on October 31, 2017, Plasson Ltd. completed the first stage of a three-stage investment in a new joint venture company with our U.S. distributor, Diversified Imports D.I.V. Co. Inc. The newly formed joint venture company, Diversified Agriculture LLC (“Diversified Agriculture”), will be responsible for all of the current Livestock activities that had been dealt with by Diversified Imports.

Plasson has now completed moves to have active and direct contact with the world’s three largest poultry markets – USA, Brazil and China.

We look forward to working together with our partners in the U.S. and enhancing Plasson’s presence in this strategic market.

IPPE 2023

Visit PLASSON Livestock booth at IPPE show, on January 24-26.2023, booth #4521